Thermal printers are widely used in retail, logistics, healthcare and other fields. There are many types of thermal printers. Most people may have the same question, that is, can thermal printers print in color?

Most thermal printers on the market currently print mainly in black, and they do not have the function of color printing. If there is a need for multi-color printing, you need to choose a two-color or multi-color thermal printer when purchasing.

Traditionally, direct thermal printers mainly output in black, but in recent years, with the advancement of thermal printing technology, some thermal printers can already print in color, but their color functions are still limited, mainly in two colors. Currently, thermal printers with multiple colors such as black-red and orange-black are available on the market.

Full-color thermal printing is still in the experimental stage, and there are difficulties such as multi-layer coating technology that is difficult to achieve, equipment limitations, and high costs. Therefore, monochrome and two-color thermal printers are more recommended when choosing.

As a professional thermal printer manufacturer, I will combine technical principles and industry progress to analyze the types and selections of thermal printing

Main Types of Thermal Printers

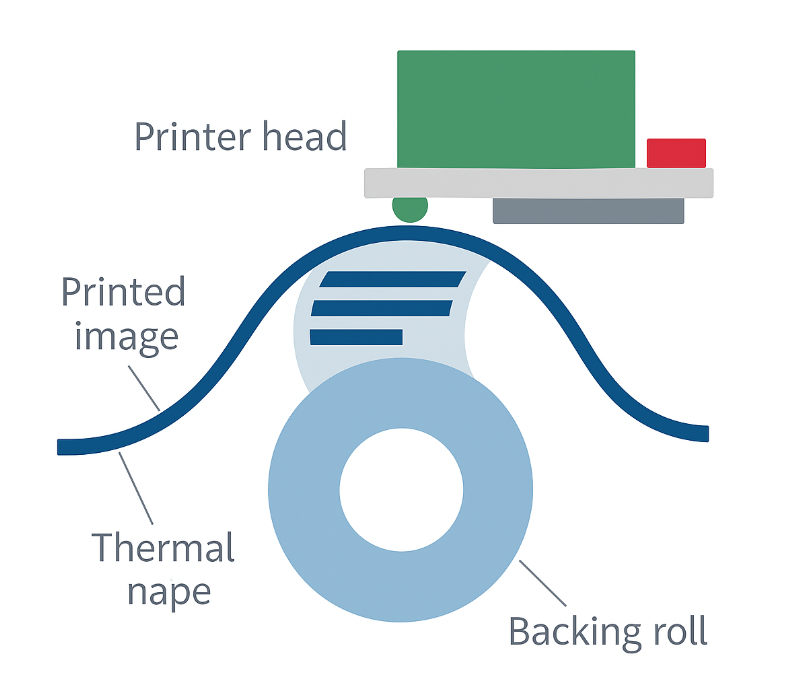

Thermal printers use heat to transfer images to paper. There are two main types of thermal printing technology: Direct Thermal Printing and Thermal Transfer Printing.

So thermal printers are generally divided into direct thermal printers and thermal transfer printers

The Principle of Traditional Direct Thermal Printer

Traditional thermal printers are based on the principle of chemical reaction color development: the print head heats a specific area, triggering the colorless dye in the thermal paper coating to react with the developer to produce a single color such as black, blue or purple.

- Color development mechanism: Thermal paper coating is composed of leuco dye and developer, which react to produce color at high temperature.

Limitations: Traditional technology only supports monochrome printing, and the coating presets the color and cannot be adjusted dynamically.

So Can Traditional Direct Thermal Printers Print Color?

No, traditional direct thermal printers cannot print in color. They are designed for use with special thermal papers that react only to heat. This means the results are only printed in black and white (or grayscale).

However, pre-printed color backgrounds can be used on thermal labels for branding or highlighting purposes, while variable data is still printed in black.

What About Thermal Transfer Printers Based on Thermal Printing?

The Principle of Thermal Transfer Printing: Uses a heated ribbon to transfer ink onto the paper or other materials.

Yes, to some extent. Thermal transfer printers can print in color—but with limitations:

- Single-color printing is common. You can change the ribbon to print in different colors such as red, blue, or green, but only one color can be used at a time.

- Full-color printing is possible but rare. It requires specialized ribbons and printers, which are more expensive and less commonly used in typical business applications.

If your goal is full-color photo-quality printing, thermal printing is not the best choice. An inkjet or laser printer would be more suitable.

Two-color Thermal Printing Solution

Two-color Thermal Label Technology

In recent years, the research and development of new materials has broken through the single-color limitation:

- Through the new coating and temperature control, two colors (such as orange and black, red and black) can be printed on the same paper to achieve differentiated printing of different information modules.

- Application scenarios: highlighting key information in logistics labels, warning signs on medical labels, etc.

Combination of Pre-printing and Thermal Printing

Fixed patterns on labels (such as brand LOGO) can be printed in color in advance, and dynamic information (such as barcodes) can be superimposed through thermal printing to reduce costs and inventory pressure.

Full-color Thermal Printing: Exploration and Challenges

Currently, full-color printing is still in the experimental stage. The technical difficulties include:

- Multi-layer coating technology: requires superimposing cyan, magenta, and yellow photosensitive layers, and achieving color mixing through precise temperature control, but the reaction speed and stability are insufficient.

- Capital and equipment limitations: Color thermal paper needs to be customized, and the printer needs to upgrade the firmware and high-precision print head, which is difficult to popularize.

Selection and Application Scenarios of Different Solutions

✅ Direct Thermal Monochrome Printing (Black & White)

Purchase Requirements:

- Proven, cost-effective and fast printing solution

- No ink, toner or ribbon required

- Ideal for short label life or one-off prints

- Clear and legible information is a top priority

- Ideal for high-volume printing environments

Application Scenarios:

- Retail: Printing receipts at checkout

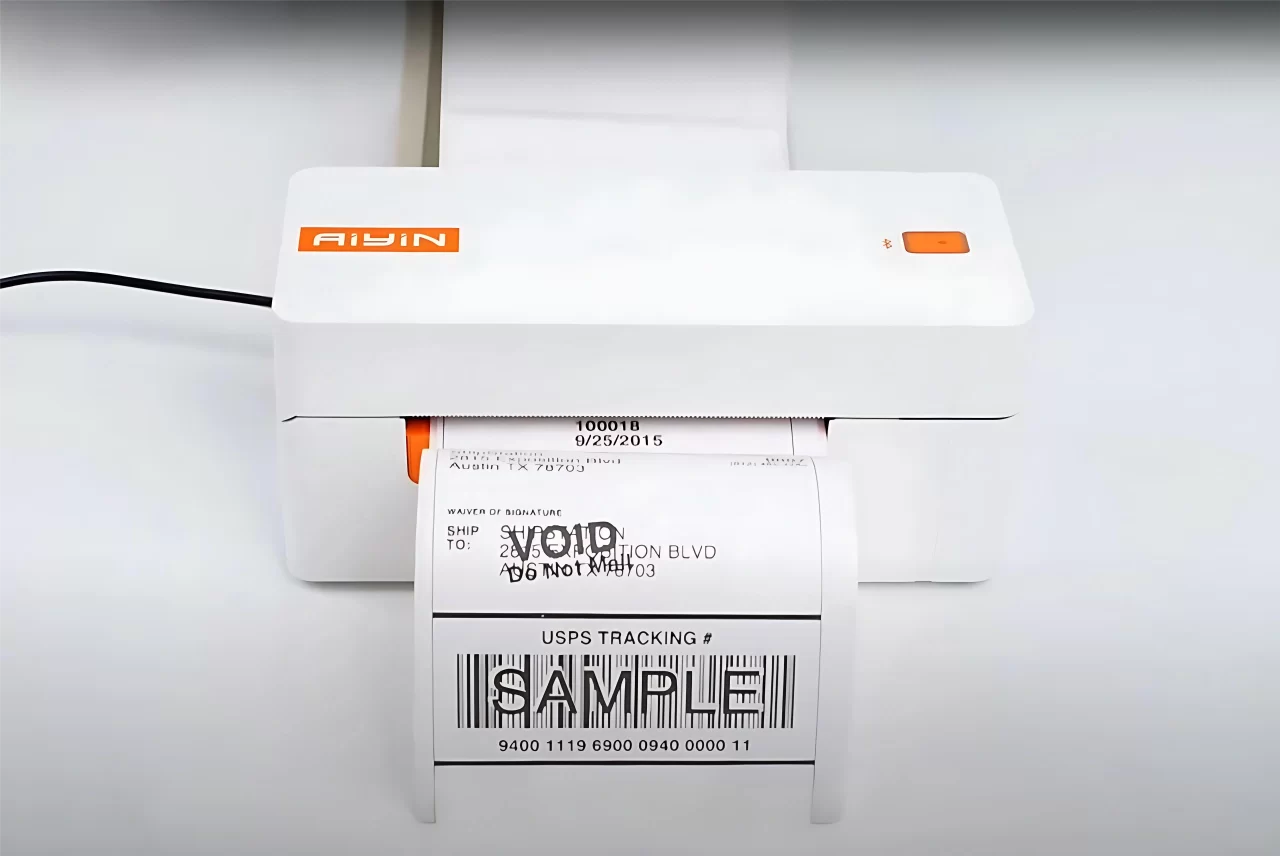

- Logistics: Shipping labels, barcodes, and tracking labels

- Healthcare: Patient wristbands, prescription labels

- Foodservice: Kitchen order tickets, price tags

✅ Direct Thermal Two-Color Printing (Typically Black + Red)

Purchase Requirements:

- Need to highlight critical information (warnings, alerts)

- Need flexibility in color placement on labels or receipts – allowing different colors to be displayed in specific areas of the paper

- Use cases where critical data needs to be quickly identified at a glance

Application Scenarios:

- Healthcare: Red highlights for allergy alerts, high-risk medication labels

- Logistics: “Fragile,” “Urgent,” or “Hazardous” notices printed in red

- Catering industry: key tags that need to be issued in catering orders

✅ Pre-Printed + Thermal Printing Labels

Purchase Requirements:

- Need to combine high-quality branding (e.g., logo, background color) with flexible variable data printing (e.g., barcodes, serial numbers, dates).

- Need to cost-effectively produce large volumes of branded labels with dynamic elements.

- Strike a balance between professional appearance and operational efficiency.

- Understand compatibility between pre-printed materials and thermal printer performance.

Application Scenarios:

- Food and Beverage Packaging: Full-color product labels pre-printed with brand visuals; thermal printing adds batch number, expiration date, and weight

- Retail: Price labels and hang tags with pre-printed branding and variable pricing or barcodes

- Pharmaceuticals: Safety-compliant labels with fixed color instructions and thermal printing to add dynamic patient or dosage information

Conclusion

Although the colorization process of thermal printing faces technical challenges, innovations such as two-color labels have opened up new scenarios for the industry.

For ordinary users, monochrome printing is still the first choice for cost-effectiveness, while corporate users can explore two-color solutions according to their needs to improve efficiency and brand image. In the future, with the iteration of technology, thermal printing may complement color inkjet and laser printing in specific fields, opening up more application possibilities